You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Catch Tank Rule Problems - VW Porsche and others please comment

- Thread starter Bob Roth

- Start date

OK, you got me on that one.Then someone needs to tell the suppliers about this.

. But, it's the same general idea, different application...

. But, it's the same general idea, different application...For grins I checked out my S4 after getting out of work tonight; it uses the external-threaded cap as illustrated above for the A3. Same idea, though: it screws onto an expansion tank that's part of the circulatory system.

My Nissan, on the other hand (I looked at my street car, but we never changed the design on the race car) uses the tried-and-true radiator blow-off cap going to an external dead-end tank. That tank *may* meet the 1-quart rule, but we'd have to measure it to be sure.

No clue off-hand what the Integra race car uses...

GA

That's exactly the expansion tank I have in my racecar - Gary, you have the part exactly right. Yes, this uses a typical radiator cap with pressure relief.

Chris, I think you're a bit wrong. The upper rad hose connects to a small nipple in the front of the exp tank, which is almost invisible in this picture. The nipple in the neck connects to a hose... which in the stock vehicle config dumps on the ground like a '66 Rustang. I've routed mine to an overflow bottle. Here's a pic:

My '82 924 Turbo does not have this tank. Rather, it has the completely closed system as has been described for the later VW's; in fact, it uses the same cap. No provision to route any overflow anywhere. The 944's IIRC use a typical rad cap... I think.

Chris, I think you're a bit wrong. The upper rad hose connects to a small nipple in the front of the exp tank, which is almost invisible in this picture. The nipple in the neck connects to a hose... which in the stock vehicle config dumps on the ground like a '66 Rustang. I've routed mine to an overflow bottle. Here's a pic:

My '82 924 Turbo does not have this tank. Rather, it has the completely closed system as has been described for the later VW's; in fact, it uses the same cap. No provision to route any overflow anywhere. The 944's IIRC use a typical rad cap... I think.

I like where this is heading, here are a couple if comments;

1) I recommend we work on the wording. Oil coolers cool the engine. There are tech inspectors that are sticklers for the wording. We owe them the respect of having rules that say exactly what is meant. Otherwise, if someone gets bounced because the chief of tech says your oil cooler doesn't have a catch can, that's what the rule says. (The GCR definition of "Cooling System - Those components directly associated with cooling the engine, including any hoses, fans, and radiators.)

2) In looking at the vw/volvo tank shown by Gary L, that car has a conventional cap and drain fitting, if you add an catch tank and you are good to go. Or with the new rule, if there is a quart of capacity in that tank, you would be fine too. Some might argue that if it were overheating, it would still probably drip some, I would be fine if that tank was required to be connected to a catch tank as its easy to do.

3) What concerns me are systems using caps with built in reliefs like the VW cap shown by Greg. I have to agree that PFCS is correct that it it must have a pressure relief in it. Otherwise a badly overheating system would be a bomb, pressurzed to 300 psi or higher. Its on cars like these that has the problems because there isn't a practical way to plumb a pressure relief line to the cap to drain the coolant in a case of overheating. Drilling a hole in the tank doesn't fix anything unless you put a relief valve in the hole as you need to keep the system pressurized to work.

1) I recommend we work on the wording. Oil coolers cool the engine. There are tech inspectors that are sticklers for the wording. We owe them the respect of having rules that say exactly what is meant. Otherwise, if someone gets bounced because the chief of tech says your oil cooler doesn't have a catch can, that's what the rule says. (The GCR definition of "Cooling System - Those components directly associated with cooling the engine, including any hoses, fans, and radiators.)

2) In looking at the vw/volvo tank shown by Gary L, that car has a conventional cap and drain fitting, if you add an catch tank and you are good to go. Or with the new rule, if there is a quart of capacity in that tank, you would be fine too. Some might argue that if it were overheating, it would still probably drip some, I would be fine if that tank was required to be connected to a catch tank as its easy to do.

3) What concerns me are systems using caps with built in reliefs like the VW cap shown by Greg. I have to agree that PFCS is correct that it it must have a pressure relief in it. Otherwise a badly overheating system would be a bomb, pressurzed to 300 psi or higher. Its on cars like these that has the problems because there isn't a practical way to plumb a pressure relief line to the cap to drain the coolant in a case of overheating. Drilling a hole in the tank doesn't fix anything unless you put a relief valve in the hole as you need to keep the system pressurized to work.

Streetwise guy

New member

The cooling system is ALWAYS designed to bleed off pressure. Always. The appearance of the cap makes no difference. Europeans tend towards the cap being on a remote bottle, with expansion room there. They also tend to spew coolant everywhere when they overheat. There is no simple solution, other than to beware of steaming Volkswagens in turn two. My Neon also spewed most of its coolant out the largish factory overflow tank when I cooked the head gasket, which makes for a very slick right rear. If a car heats badly enough, it will spew on something. Mine is now set up to spew on the windshield instead of the tires..

.

.

Flyinglizard

New member

How about a minimum catch tank size, either the stock expansion tan( IE german stuff) or the traditional overflow tank, .

Either way there should be a qt allowed for overflow. 1 Qt of airspace in the top of the VW tank ,or 1qt at the end of the overflow hose, on a Mustang.

Why have any new wording at all ? Every one had pretty much what was needed. Techs seemed to let it go as raced.

MM

Either way there should be a qt allowed for overflow. 1 Qt of airspace in the top of the VW tank ,or 1qt at the end of the overflow hose, on a Mustang.

Why have any new wording at all ? Every one had pretty much what was needed. Techs seemed to let it go as raced.

MM

Z3_GoCar

New member

Bob, a couple of points.

- First, "coolant", in most common-usage of the word, refers to the water-based portion of the engine cooling systems. There's no intent here to apply this to anything else.

- Second, the intent of this rule, as I read it, is to ensure that open, blow-off systems, such as what's on most 'Merican cars, have tanks of sufficient size to capture all coolant that may bleed when the engine gets hot. Volkswagens do not have a "catch tank" per se; the V-dub (and Audi and presumably Porsche) system is a fully-enclosed, flow-through system. The plastic tank you see is nothing more than a convenient reservoir/expansion tank, and is actually part of the cooling flow circuit.

I see no application of this rule to either lubrication oils nor to flow-through systems such as the VW/Audi example. At worst there may need to be a simple edit to the proposed rule that this would not apply to fully-enclosed, non-blow-off, flow-through systems.

GA

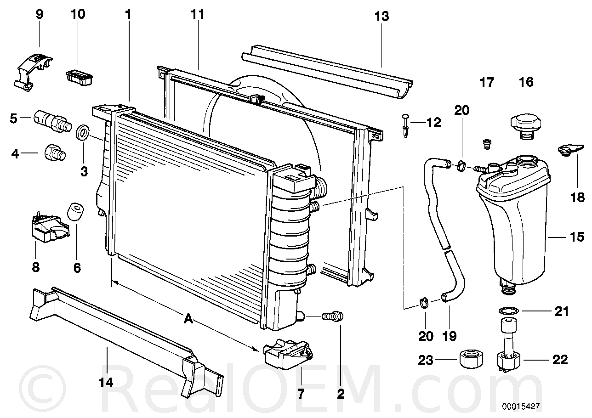

Greg, you can add certain years of BMW's to that list too:

This the radiator assembly that's in my car now. If I went with an aftermarket aluminum unit, then I could see adding an additional tank, but on the stock system there's no place to add anything, not even a hole in the radiator neck.

Huh. Surprising that the 924 has a non-VW style system, when it was conceived and designed as a VW originally. Learn something new every day.

Going back 24 years ago when my dad and I were rebuiling the motor to my Audi 100, we were told by some parts guy that the 924 motor was sourced from Audi, not VW, and so it makes sense that they'd use an Audi type expansion bottle.

I have to wonder how many drivers feel a need for this new rule?

I never found spilling coolant to be a problem on the track from overheating. When a car overheats, the voiding starts slowly after a lot of steam and generally is of minimal danger. More often, something comes apart, breaks, or is broken, resulting in a fast/large leak, none of which would be collected by a catch tank.

I never found spilling coolant to be a problem on the track from overheating. When a car overheats, the voiding starts slowly after a lot of steam and generally is of minimal danger. More often, something comes apart, breaks, or is broken, resulting in a fast/large leak, none of which would be collected by a catch tank.

How about this?

Coolant Catch Tanks; Cooling systems that have a hose nipple at the pressure relief cap shall have a coolant catch tank that has a minimum capacity of 1 US quart. Cooling systems having a pressurized reservoir that allows a minimum of 1 quart vapor space under normal coolant levels between the coolant and pressure relief cap are exempted from this rule. OEM cooling systems on DOT approved cars that do not have a hose nipple at the pressure relief cap are exempted from this rule as long as the cooling system retains the OEM pressure relief cap assembly.

Reasoning;

1) This rule would apply to cooling systems having a pressure relief cap. Oil cooling systems do not have pressure relief caps, therefore this rule cannot apply to them.

2) Some OEM DOT approved car cooling systems (VW and others) have their pressure vents built into the pressure relief caps and do not have a nipple. This exempts IT and Touring cars having their original pressure relief cap assembly, avoiding for their owners the expense of fabricating custom tanks and pressure relief caps.

3) This rule applies to all classes including GT and formula. By limiting the exemption to OEM cooling systems on DOT cars, it prevents custom systems having neither a vapor space nor a catch tank.

I think its important that the rule be clear as to where it applies. Also, I think it has to address cars which do not have a relief nipple, or that have more than 1 qt internal space. Please comment.

Coolant Catch Tanks; Cooling systems that have a hose nipple at the pressure relief cap shall have a coolant catch tank that has a minimum capacity of 1 US quart. Cooling systems having a pressurized reservoir that allows a minimum of 1 quart vapor space under normal coolant levels between the coolant and pressure relief cap are exempted from this rule. OEM cooling systems on DOT approved cars that do not have a hose nipple at the pressure relief cap are exempted from this rule as long as the cooling system retains the OEM pressure relief cap assembly.

Reasoning;

1) This rule would apply to cooling systems having a pressure relief cap. Oil cooling systems do not have pressure relief caps, therefore this rule cannot apply to them.

2) Some OEM DOT approved car cooling systems (VW and others) have their pressure vents built into the pressure relief caps and do not have a nipple. This exempts IT and Touring cars having their original pressure relief cap assembly, avoiding for their owners the expense of fabricating custom tanks and pressure relief caps.

3) This rule applies to all classes including GT and formula. By limiting the exemption to OEM cooling systems on DOT cars, it prevents custom systems having neither a vapor space nor a catch tank.

I think its important that the rule be clear as to where it applies. Also, I think it has to address cars which do not have a relief nipple, or that have more than 1 qt internal space. Please comment.

JimLill

New member

on my VW I split an expansion tank open when the fan failed to run, thankfully in my driveway! So the rule hardly covers that but the 2 things lead me towards some research.

- the tank split because my cap was bad

- on that VW, the caps releases at 17-19 psi

So my plan is to conform to the rule with an add-on relief valve to a puke bottle rather than buy a new cap (I'll defeat the cap port altogether)

- the tank split because my cap was bad

- on that VW, the caps releases at 17-19 psi

So my plan is to conform to the rule with an add-on relief valve to a puke bottle rather than buy a new cap (I'll defeat the cap port altogether)

rsportvolvo

Member

**this applies to closed systems as use on newer cars

If the coolant system is over-pressurized then something will eventually meet it's design limit and fail. The purpose of the pressure relief cap is to save more expensive items in the coolant system. I'm not sure about VAG cars, but Volvo offers 3 different cap designs (0.75 bar, 1.0 bar, 1.50 bar) for their expansion tank (not a catch can as the coolant can and does drain back into the radiator). At $5.00 each I can afford to have a tested spare.

The closed loop expansion tank is a puke can for the radiator. Adding a puke can for the puke can seems silly. (added)

How many folks get a new expansion tank or trust the old one to hold up? I'm sure many of the older tanks are reaching their brittle fracture pressure limit (BFPL) after 10+ years of heat cycling. Instead of reinventing the closed loop expansion tank systems common to most newer cars, howabout using a fresh expansion tank and pressure cap? Then pressure testing before hitting the track.

If the coolant system is over-pressurized then something will eventually meet it's design limit and fail. The purpose of the pressure relief cap is to save more expensive items in the coolant system. I'm not sure about VAG cars, but Volvo offers 3 different cap designs (0.75 bar, 1.0 bar, 1.50 bar) for their expansion tank (not a catch can as the coolant can and does drain back into the radiator). At $5.00 each I can afford to have a tested spare.

The closed loop expansion tank is a puke can for the radiator. Adding a puke can for the puke can seems silly. (added)

How many folks get a new expansion tank or trust the old one to hold up? I'm sure many of the older tanks are reaching their brittle fracture pressure limit (BFPL) after 10+ years of heat cycling. Instead of reinventing the closed loop expansion tank systems common to most newer cars, howabout using a fresh expansion tank and pressure cap? Then pressure testing before hitting the track.

Last edited:

JimLill

New member

The closed loop expansion tank is a puke can for the radiator. Adding a puke can for the puke can seems silly. (added).

The euphemism "puke can" refers to a vessel that keeps expelled fluids from going into the air or onto the ground. When pressure cap on an expansion tank lets go, where do the fluids go? Ergo, how can the expansion tank be a puke can?

rsportvolvo

Member

The euphemism "puke can" refers to a vessel that keeps expelled fluids from going into the air or onto the ground. When pressure cap on an expansion tank lets go, where do the fluids go? Ergo, how can the expansion tank be a puke can?

The volume require to relieve system pressure is quite small. The expansion tank will contain the fluid in most cases and any released fluid will most likely be in a gaseous state. Your case was a catastrophic failure of the expansion tank. The expansion tank is a puke can for the radiator. Having a pressurized tank that has the ability to drain back into the radiator makes it a close loop system.

Your issue with the expansion tank was due to faulty components, not a faulty design. So instead of changing the design (proven over the years and approved by DOT and TUV) the components should be tested before hitting the track. Did you test the cap afterwards to confirm the cap was the culprit vs. the tank?

The puke can addition would really only apply to the radiator cap setups use on many Japanese cars and older American cars.

I'm just playing devil's advocate here. Ultimately it's up to the car owner/driver and the local scrutineer's to say if the setup is safe and meets the letter of the law.

JimLill

New member

I'm just playing devil's advocate here. Ultimately it's up to the car owner/driver and the local scrutineer's to say if the setup is safe and meets the letter of the law.

so am I....... my failure only led me to do research and has nil to do with on my take on what, if anything, I need to do to be legal.