Hi everyone, happy holidays...

My brother might get mad at me for disclosing this info but oh well...

$50.00 or so for a 200,000 mile used motor (little rusty).

$300 machine work, all basic no high tech refresher stuff.

$200.00 or so on gaskets/new rings/oil/antifreeze, and other odds and ends. Again nothing fancy.

Total cost for a 2.2L winning ITB Audi motor: $500 - $600. Best thing is that the engine is basically stock and lasts another 200,000 miles... that is a lot longer than 2 race seasons

You could go nuts and have 40 over pistons made (none available) and you could go nuts balancing and blueprinting but I trust those Audi enginears did a good enough job... Oh and we could get the intake and exaughst port matched 1" in, but agian to much $$$.

Truth of the matter is we can't afford it. If we could then we might try it in 1 car to see what sort of actual gains you get.

I think that most IT drivers have many other areas that they should consentrate on gaining time. Whenever we look at what to do next on the Audi's we deffinatly look at the cost/time factor and see where we can get the biggest "bang for the buck."

I also will boldly say that I think many of the "front runners" are "front runners" because of car setup/suspension and driving capabilities, not motor. For example my brother and I have basically equal motors, however he has a different suspension setup. His car is 1-2 seonds a lap faster no matter who is driving (me or him). I could add as much motor as I wanted but that wont do anything in an IT car... That 5% gain will only help you win when you have everything else maxed out.

Those who have the money please spend it, it keeps those tunners that keep this sport going in business!!!

Raymond Blethen

------------------

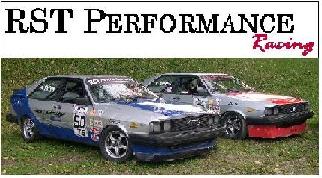

RST Performance Racing

www.rstperformance.com

1st and 2nd 2003 ITB NARRC Championship

1st and 6th 2003 ITB NERRC Championship

3rd 2003 ITB ARRC Sprint Race

4th 2003 ITB ARRC Endoro

1st 2003 AS NERRC and NARRC Championships