You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ITS Ford Mustang(s) Build - Stripper Stang Part II

- Thread starter Ron Earp

- Start date

Ron Earp

Administrator

Mustangs did really well. 23s on the test day and a 22.7 for one lap in the race.

With no draft either. I think if I'd had the benefit of the S-car train upfront then I'd be a bit faster. And if I'd man up and just hold the loud pedal down everywhere, well, that would help too.

Ron Earp

Administrator

Thanks for the kind words. It has come at a price though, probably over 900 man-hours in the garage for us with lots of on-track testing followed by many changes based on the data collected. I don't know, but I suspect we've got the IT record for the most hours of building, development, and testing in the shortest amount of time for these two cars. Wife doesn't like it.

So, with that in mind I'm leaning toward VIR being the last race for the cars. At least, it will be the last race for both cars as the red one is going to sleep for the winter. It could be we still take the green one to the last SCCA Road Atlanta race for the year but that sort of depends on my tire situation after this weekend. My tires are getting near the end and I won't buy a new set this year as the budget ist kaput.

So, with that in mind I'm leaning toward VIR being the last race for the cars. At least, it will be the last race for both cars as the red one is going to sleep for the winter. It could be we still take the green one to the last SCCA Road Atlanta race for the year but that sort of depends on my tire situation after this weekend. My tires are getting near the end and I won't buy a new set this year as the budget ist kaput.

Ron Earp

Administrator

Care to estimate what you've spent building the car? Or is that like asking a woman's age?

Unfortunately, I know exactly how much I've spent as every part number, cost, and source are in a spreadsheet. I have written before on this thread, and I've said it to folks in the paddock that ask, if you wish to build the car like we have built it is not cheap, at least not by my standards. Factoring in what we know and the cost savings from that knowledge I still feel the build will be around $20k-$23k with a decent donor car. However, I'm sure an ITS Mustang could be built for $5k, $8k, $12k, - you pick the number.

I don't think a 95%+ Mustang build will be a low-cost-leader in ITS. There are a lot of parts that simply cost a certain amount and will require that initial investment to obtain. And, regardless of the cost, you can't get around the time component in anyway, except with the checkwrench. There is a lot of work and development to be done, lots of detailed engine tuning that needs to happen, and so on. You pay for that with time or money, we chose time, and still spent a lot of money. If we'd used the checkwrench it'd have cost more.

There are simply many other well-developed chassis in ITS that are known quantities which can be built to be faster than the Mustang based on known formulas. Everyone gets attracted to the Mustang because "There is a V6 5 speed on Craigslist for $750", and that is true. But one might be better off starting with a $3000 E30/RX7/Miata/240Z/280Z etc. if they're interesting in skipping the learning curve, going fast, and racing.

Last edited:

Ron Earp

Administrator

VIR Goblins's Go Team Mustang Report

Team Mustang had a pretty decent showing this past weekend at VIR. We entered the two Mustangs into the Saturday ECR as "Team Ron" and "Team Jeff". Team Jeff was Jeff Young and Jeff Giordano, Team Ron was Ron Munnerlyn and Ron Earp.

Both teams finished and did well, second place for Team Jeff and third place for Team Ron.

Ron Munnerlyn turned the fastest lap for the Mustangs with a 2:17 and ran consistent 2:19s with some traffic and aging tires. Nice job Ron and as far as I'm concerned a 2:17 shows me that we're in the hunt and with more development and driving we can get to the pointy end S times. Ron's fastest lap is here:

I didn't drive very well throughout the entire weekend. While I did okay in the enduro with some 19s once I settled in, it took me a long time to settle in. I also didn't qualify too well for Sunday's SARRC race either which put me starting 5th or 6th.

And, my driving didn't improve for Sunday. I ended up pinching Scott Finlay off in T3 which resulted in me being bumped off the turn. Fortunately Scott and the other cars were able to continue and no other cars received any damage.

https://vimeo.com/51889655

[ame]http://www.youtube.com/watch?v=2lUfOvK6DlM[/ame]

After the impact I felt the rear end had a weird vibration and my head just wasn't in the game. The vibration, of course, turned out to be two huge handfuls of gravel/tire buggers which got scooped up into the inside of the wheel in the off, no big deal. But, since I'd not had any metal to metal contact in over six years I was a bit shook up and came in.

The weekend was successful for R&D though. As usual, we had experiments underway and collected more data on yet another rear end ratio for the Mustangs. I think we're close to selecting the right ratio but we'll need to have a closer look at what we have.

Anyhow, that ends the season for Team Mustang. Off-season plans are already underway and we've got a fair amount planned to do before 2013. Time to get to work, but before the Mustangs get new trannies, engines, etc. I'm going to finish up that Torino that has been languishing in the background for awhile...

Team Mustang had a pretty decent showing this past weekend at VIR. We entered the two Mustangs into the Saturday ECR as "Team Ron" and "Team Jeff". Team Jeff was Jeff Young and Jeff Giordano, Team Ron was Ron Munnerlyn and Ron Earp.

Both teams finished and did well, second place for Team Jeff and third place for Team Ron.

Ron Munnerlyn turned the fastest lap for the Mustangs with a 2:17 and ran consistent 2:19s with some traffic and aging tires. Nice job Ron and as far as I'm concerned a 2:17 shows me that we're in the hunt and with more development and driving we can get to the pointy end S times. Ron's fastest lap is here:

I didn't drive very well throughout the entire weekend. While I did okay in the enduro with some 19s once I settled in, it took me a long time to settle in. I also didn't qualify too well for Sunday's SARRC race either which put me starting 5th or 6th.

And, my driving didn't improve for Sunday. I ended up pinching Scott Finlay off in T3 which resulted in me being bumped off the turn. Fortunately Scott and the other cars were able to continue and no other cars received any damage.

https://vimeo.com/51889655

[ame]http://www.youtube.com/watch?v=2lUfOvK6DlM[/ame]

After the impact I felt the rear end had a weird vibration and my head just wasn't in the game. The vibration, of course, turned out to be two huge handfuls of gravel/tire buggers which got scooped up into the inside of the wheel in the off, no big deal. But, since I'd not had any metal to metal contact in over six years I was a bit shook up and came in.

The weekend was successful for R&D though. As usual, we had experiments underway and collected more data on yet another rear end ratio for the Mustangs. I think we're close to selecting the right ratio but we'll need to have a closer look at what we have.

Anyhow, that ends the season for Team Mustang. Off-season plans are already underway and we've got a fair amount planned to do before 2013. Time to get to work, but before the Mustangs get new trannies, engines, etc. I'm going to finish up that Torino that has been languishing in the background for awhile...

RacerBowie

New member

I thought you were coming to the ARRC?

Ron Earp

Administrator

I thought I might, but the family situation at the moment is not conducive to me obtaining a kitchen pass. The SIC / Goblin's Go / AARC is hard to do with only a weekend in-between each one. Throw the 13hr in there for consideration and there is just too much racing in five weeks.

Ron Earp

Administrator

Work progressed at the Mustang ranch this weekend. The red car developed a strong lifter noise after the ECR at VIR and since it was slated for Engine V2.0 this winter we went ahead and pulled it. It's sitting on the stand in front of the Torino.

Using the data collected from VIR Jeff G put together a MatLab simulation to model the cars accelerating down the straight at VIR to help us with gear selection. I believe the right gear ratio has been sorted out so we'll have to build up two new axles for those. The gears are cheap and the axles inexpensive that it makes sense to use the ones we have for spares and just build new one with a different ratio.

Sleestak is also getting motor V2.0 for 2013. I'm fairly certain we can get a bit more power with a new engine build and new exhaust design. Maybe as much as 3-5%, but it is hard to predict.

A major weight loss program for the cars is also being assembled. We think that we can re-design some of our added suspension parts to drop a significant amount of weight. Also, there are numerous other places to drop a few pounds - eliminate wheel spacers, new seat, exhaust, etc. and we estimate a 4% reduction in overall weight. 4% less weight and 4% more power would be alright.

Currently the green car is shod with street tires and exhaust with catalytic converter so we can take it for NC inspection and make the registration current. With new motors going in during 2013 a street tag will greatly facilitate engine break in and shake down. After that occurs the green one moves to the house garage and the Torino takes over the workshop.

Using the data collected from VIR Jeff G put together a MatLab simulation to model the cars accelerating down the straight at VIR to help us with gear selection. I believe the right gear ratio has been sorted out so we'll have to build up two new axles for those. The gears are cheap and the axles inexpensive that it makes sense to use the ones we have for spares and just build new one with a different ratio.

Sleestak is also getting motor V2.0 for 2013. I'm fairly certain we can get a bit more power with a new engine build and new exhaust design. Maybe as much as 3-5%, but it is hard to predict.

A major weight loss program for the cars is also being assembled. We think that we can re-design some of our added suspension parts to drop a significant amount of weight. Also, there are numerous other places to drop a few pounds - eliminate wheel spacers, new seat, exhaust, etc. and we estimate a 4% reduction in overall weight. 4% less weight and 4% more power would be alright.

Currently the green car is shod with street tires and exhaust with catalytic converter so we can take it for NC inspection and make the registration current. With new motors going in during 2013 a street tag will greatly facilitate engine break in and shake down. After that occurs the green one moves to the house garage and the Torino takes over the workshop.

Last edited:

...

Using the data collected from VIR Jeff G put together a MatLab simulation to model the cars accelerating down the straight at VIR to help us with gear selection...

Finally, justification for reading IT.com at work! I'd love to see the models and MATlAB code you guys are using (always on the lookout for interesting user applications here at MathWorks)..

Ron Earp

Administrator

Matlab code is up to Jeff G so he'll have to chime on on that. We do know this, the differences with the ratios are so close you'll never feel it. You'd have to have solid track data or simulation results to pick the best ratio, at least for our cars. I think a peaker motor would make it easier, but with a broad powerband it is difficult.

Hate I'm missing the Road Atlanta race this weekend but the Mustang Ranch is still in operation. As previously mentioned, Jeff G's motor developed a nasty tick after the ECR at VIR (2nd place finish, first wood for the red car, woo!). So we pulled the motor last weekend and tore it down last night and today. Thanks Flatout guys for the t-shirt catching oil. It was used up with a huge tear down the backside though and lived a happy life until the end.

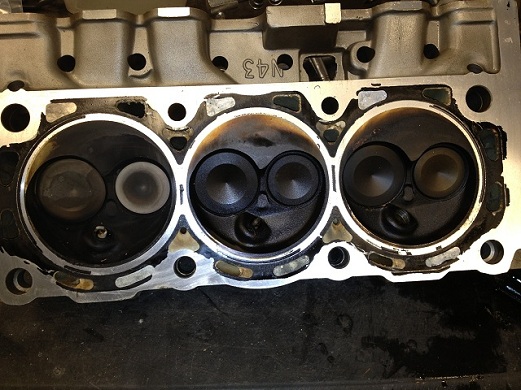

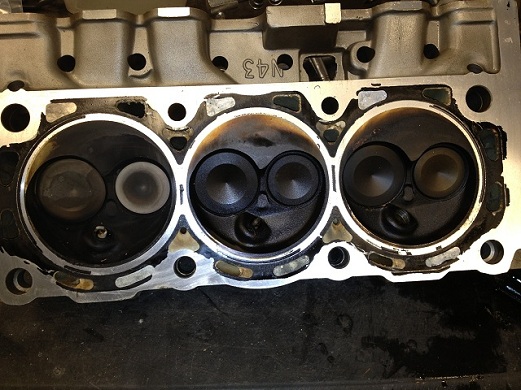

These motors are quite involved to extract and take more time to tear down than an inline engine. Most everything looked pretty good on the heads, that is to say, they sealed up nicely (leak down and compression results very good but that was a week BEFORE the tick) although one or two cylinders on each side was a bit wet with oil.

Exhaust port #3 was fairly soaked.

Intake dry though. Sorry the picture sucks but you can see the port matching almost an inch in, and after that it was quite dry and just a bit of carbon fluff. These heads flow well without any work needed, which is good, since we can't do anything in IT anyhow. But they are a very different animals from a stock 5L V8 head if anyone here has experience with those.

Hate I'm missing the Road Atlanta race this weekend but the Mustang Ranch is still in operation. As previously mentioned, Jeff G's motor developed a nasty tick after the ECR at VIR (2nd place finish, first wood for the red car, woo!). So we pulled the motor last weekend and tore it down last night and today. Thanks Flatout guys for the t-shirt catching oil. It was used up with a huge tear down the backside though and lived a happy life until the end.

These motors are quite involved to extract and take more time to tear down than an inline engine. Most everything looked pretty good on the heads, that is to say, they sealed up nicely (leak down and compression results very good but that was a week BEFORE the tick) although one or two cylinders on each side was a bit wet with oil.

Exhaust port #3 was fairly soaked.

Intake dry though. Sorry the picture sucks but you can see the port matching almost an inch in, and after that it was quite dry and just a bit of carbon fluff. These heads flow well without any work needed, which is good, since we can't do anything in IT anyhow. But they are a very different animals from a stock 5L V8 head if anyone here has experience with those.

Last edited:

Ron Earp

Administrator

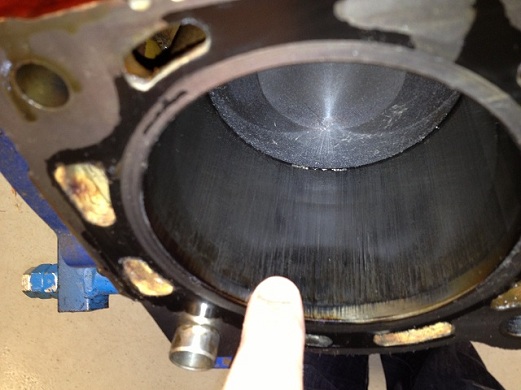

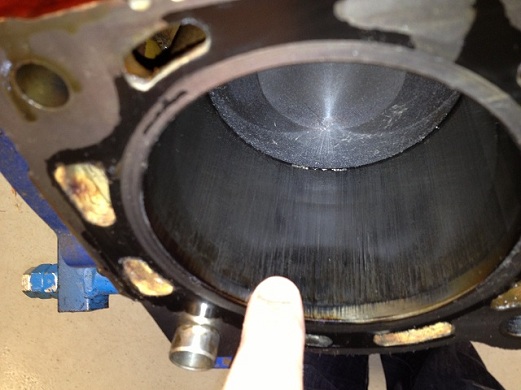

The cam and lifters were at least happy. Don't mind the oil stains and stuff in the valley, lots of turning the engine over on the stand ended up with staining, drips, and unsightly messes left behind. With the heads off we could tell that four cylinders have fairly bad scoring.

The pistons too have scoring, of course, and those same four are damaged. Well, fair to say all of them have some marks but four of them are worse than the others. Crosshatching is only visible in two of the cylinders. As we got further along into it and getting the bottom end it became apparent the oil pan had clues.

With the pistons and rods out we could tell that all the rod bearings are heavily worn and damaged. One appears to have spun, but they all have seen hard times.

The mains also have bearing damage and the crank, while usable, will have to be turned for the next service. Basically, we've got a motor that is essentially worn out. We have a few theories as to the why but we need to make more measurements and collect data before to know what happened. We think we know what the problem is and it ain't us.

This motor only made it about 24.5 hrs of run time before we pulled it. The oil pressure was perfect, still made power, but it also made a lot of noises. The green car's motor has 30.5 hours on the clock, completely silent, and is going strong though.

So we're off to the machine shop for a few discussions, measurements, and machining. The bad thing is that this block was already bored 0.040" and is now a large paper weight as far as IT is concerned. The good news is that our local Mustang breaker in Henderson has a 96 V6 with blown head gaskets for $100, and, we've got two blocks upstairs and one complete stock running engine up there too. Tomorrow morning we're off to Henderson to do a bit of shopping for spare parts and other rare Mustang treasures.

The pistons too have scoring, of course, and those same four are damaged. Well, fair to say all of them have some marks but four of them are worse than the others. Crosshatching is only visible in two of the cylinders. As we got further along into it and getting the bottom end it became apparent the oil pan had clues.

With the pistons and rods out we could tell that all the rod bearings are heavily worn and damaged. One appears to have spun, but they all have seen hard times.

The mains also have bearing damage and the crank, while usable, will have to be turned for the next service. Basically, we've got a motor that is essentially worn out. We have a few theories as to the why but we need to make more measurements and collect data before to know what happened. We think we know what the problem is and it ain't us.

This motor only made it about 24.5 hrs of run time before we pulled it. The oil pressure was perfect, still made power, but it also made a lot of noises. The green car's motor has 30.5 hours on the clock, completely silent, and is going strong though.

So we're off to the machine shop for a few discussions, measurements, and machining. The bad thing is that this block was already bored 0.040" and is now a large paper weight as far as IT is concerned. The good news is that our local Mustang breaker in Henderson has a 96 V6 with blown head gaskets for $100, and, we've got two blocks upstairs and one complete stock running engine up there too. Tomorrow morning we're off to Henderson to do a bit of shopping for spare parts and other rare Mustang treasures.

Ron Earp

Administrator

The motor is apart and all pertinent parts down to the machine shop. Today we checked the rotating assembly for initial balance in the configuration that it failed. It did have a minor imbalance. Also this week, the driveshaft was checked for balance, It was found to be seriously out of balance and definitely contributed to the odd vibrations and failed transmission in the red car. Check and double check the balance of stock drive shafts.

Two new Mustang motors are underway and we're pretty sure we'll put down more power than we did with V1.0. VTEC Yo! and the Tumbling Doritos best watch out!

Two new Mustang motors are underway and we're pretty sure we'll put down more power than we did with V1.0. VTEC Yo! and the Tumbling Doritos best watch out!

Last edited:

Ron Earp

Administrator

Hmmm, the cost of Mustang fun might have just gone up considerably. Ford doesn't have any overbore size pistons available for 96-98 Mustangs, just select fit sizes A,B,C that only clean up very minor differences in bore out in the thousands and ten thousandths. The price is right though, $29 per hole.

The 01-04 3.8L V6 piston is a replacement for the earlier piston but there are only five showing across the entire country and they don't all match in overbore. Clearly Ford isn't interested in you rebuilding a 1998 V6 Mustang engine, I suppose they want you to toss your stripper mobile and get another one. Fortunately there are other piston suppliers and I'm sure we can locate some pistons in the proper diameter.

The 01-04 3.8L V6 piston is a replacement for the earlier piston but there are only five showing across the entire country and they don't all match in overbore. Clearly Ford isn't interested in you rebuilding a 1998 V6 Mustang engine, I suppose they want you to toss your stripper mobile and get another one. Fortunately there are other piston suppliers and I'm sure we can locate some pistons in the proper diameter.

adamjabaay

New member

just read the whole thread. Awesome job guys. Awesome. gave me great motivation to finish the work on my ITA car

Ron Earp

Administrator

Glad you enjoyed the thread and got something out of it.

Not much new to report on the ITS Mustangs. Both are getting new engines although my car seems to have a healthy engine. I figured if we're building one new engine we might as well build two.

We now suspect that neither engine was bored with a torque plate. Why? Well, searching high and low in automotive machine shop suppliers we can't find a Ford 3.8L torque plate. The bore/bolt spacing is specific for that engine, that is it isn't just a 302 or other V8 with two cylinders lopped off. If we can't find one we are starting to wonder if the folks that did the original engines had one themselves. We're not getting a lot of feedback from them once we explained the rotating assembly from one engine was out of balance.

Anyhow, we're having a torque plate made in aluminum and it'll be finished up next week. Pistons were ordered and various parts have been sent out for inspections, in particular a few sets of heads to get some solid numbers of castings and flow characteristics. We're also waiting on some new multiple part crank scrapers and windage trays to replace the simplistic pieces we had in V1.0. And, we have some new merge collectors on order as well as some extremely lightweight Burns mufflers. Onward.

Not much new to report on the ITS Mustangs. Both are getting new engines although my car seems to have a healthy engine. I figured if we're building one new engine we might as well build two.

We now suspect that neither engine was bored with a torque plate. Why? Well, searching high and low in automotive machine shop suppliers we can't find a Ford 3.8L torque plate. The bore/bolt spacing is specific for that engine, that is it isn't just a 302 or other V8 with two cylinders lopped off. If we can't find one we are starting to wonder if the folks that did the original engines had one themselves. We're not getting a lot of feedback from them once we explained the rotating assembly from one engine was out of balance.

Anyhow, we're having a torque plate made in aluminum and it'll be finished up next week. Pistons were ordered and various parts have been sent out for inspections, in particular a few sets of heads to get some solid numbers of castings and flow characteristics. We're also waiting on some new multiple part crank scrapers and windage trays to replace the simplistic pieces we had in V1.0. And, we have some new merge collectors on order as well as some extremely lightweight Burns mufflers. Onward.

lateapex911

Super Moderator

Impressive as always. Proper build. Well done, and THANKS for the continued updates. I don't respond every time you update teh thread, but know that I read, learn and enjoy.

Happy Holidays, Ron, Jeff, (And the other traitor w a British V8), Jeff.

(As an aside, you guys have it out of phase: A V6 American race car, and a V8 British race car? So wrong, LOL)

Happy Holidays, Ron, Jeff, (And the other traitor w a British V8), Jeff.

(As an aside, you guys have it out of phase: A V6 American race car, and a V8 British race car? So wrong, LOL)